Behind the build: what it’s like working with Recticel on flat roof projects

When specifying insulation for a flat roof project, there’s more to consider than U-values.

Architects, contractors, consultants, and specifiers need to balance competing priorities: product performance, compliance, cost, space constraints, fire safety, delivery timelines, technical support, and more.

That’s why you need an insulation partner who understands your brief and helps overcome technical challenges before they become problems on site.

To understand what a working partnership with Recticel looks like, we caught up with Ashley Shapiro, Project Manager and Director at Bluestorm Consulting, who recently worked with Recticel on an office extension project in North West London.

Solving complex flat roof challenges with limited build-up depth

Located in Portsdown Mews, London, the project involved a two-storey extension to an existing office building with a flat roof.

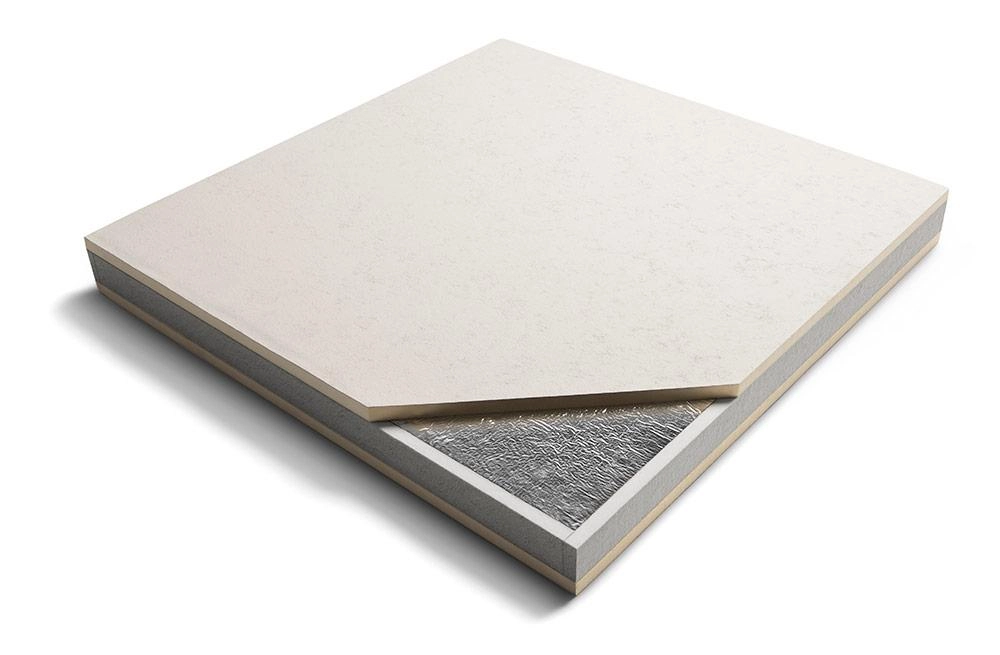

Deck-VQ®, a Vacuum Panel Insulation (VIP) manufactured by Recticel, played a key role in delivering an efficient, slim build-up while also meeting thermal and fire performance requirements.

“One of the challenges at Portsdown Mews was the limited ceiling height and, therefore, the overall construction thickness of the roof,” explains Ashley. “I needed the insulation to be as thin as possible without compromising thermal resistance,” he adds. “Instead of having >150 mm, we needed to keep insulation <70 mm, so Deck-VQ® at 60 mm was the perfect board for this application.”

At 60 mm, Deck-VQ® achieves a Lambda of 0.008 W/mK, making it ideal for flat roofs with limited space. It helps architects, contractors, and consultants like Ashley deliver the thermal performance and U-values they require without taking up additional space in the roof build-up.

Why Bluestorm Consulting chose Deck-VQ® over the competition?

Ashley selected Deck-VQ® for its robust packaging and ease of handling. “Deck-VQ® comes encased in what looks like a little briefcase,” he explains. “The sensitive vacuum foil wraps inside are completely protected – and the marginally lower declared thermal conductivity is a bonus.

“You would have to make an effort to damage them. The installers hadn’t seen anything like it before and remarked how good it was to handle, which removed any anxieties about installing a new type of product.”

From design to install: how does Recticel’s support make the difference?

For construction professionals, trust in an insulation partner is essential. But it’s also earned – through product performance, clear and responsive support, and smooth delivery at every stage.

As Ashley states: “I want to work with people who are responsive, understand their products, and can give me clear answers to help solve project challenges. Recticel were responsive and always happy to help when drawings needed changing, so I’ll be sticking with them going forward.”

On-site layout guidance that made installation seamless

Support should extend from one end of the project to another. Ashley highlights how the Recticel Technical Services team provided clear layout instructions that made installation easier on site.

“Installing Deck-VQ® was really simple,” he says. “It was a matter of connecting the dots because we were given easy-to-follow, colour-coded layout instructions.

“At perimeters and junctions, there’s also a cuttable infill section, so you’ve got flexibility in case there’s a tolerance that’s out, which helps when navigating edges, penetrations, and junctions."

How Recticel supports your project?

For Ashley, the outcome of the Portsdown Mews project wasn’t just a successful install. From product performance to technical support, it was a positive experience from start to finish. “I’ve only got good things to say about working with the Technical Services team at Recticel,” he says.

“It was a really good experience, and I will definitely be choosing Recticel and Deck-VQ® again. Having handled it and laid it, I know it will now be my go-to product when I need VIP insulation.”

Deck-VQ

With a thermal performance of the core of lambda 0.006, it's the ideal solution for your renovation or new build projects with ease. Deck-VQ offers long-term performance whilst maintaining the existing roof structure, thereby avoiding costly modification.

Our Deck-VQ is CCPI assessed, as noted in the assessment marking that can be seen in the images.

For test certificates please contact our technical department for details