Designing for reuse & recycling

🡄 Go to sustainability overview

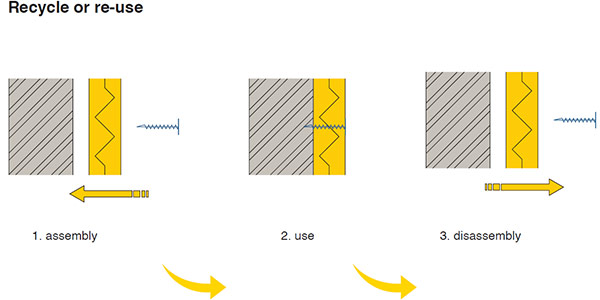

The majority of our carbon footprint comes from our raw materials and waste management. If we want to get that percentage down and achieve full circularity, we need to rethink how our PIR insulation boards are made in the first place and design them with their end of life in mind. By applying the principles of eco-design, we want to create systems that are easy to disassemble and recover for reuse and recycling.

Progress status

| 🚀 STAGE | Study 🡆 Lab test 🡆 Pilot trial 🡆 Launch 🡆 UPSCALING |

| 📈 NEXT STEP | Promote the use of detachable systems |

Project description

What is it?

The idea of eco-design is to maximize the recyclability and reusability of products and buildings by designing them in such a way that they can easily be disassembled and recovered.

““Eco-design means designing products that last a lifetime and are easy to detach, recycle and re-use. That’s exactly what we want to achieve by thinking in ‘systems’ rather than ‘materials’.””

How do we do it?

Our objective is to rethink the way our PIR insulation boards are attached to the walls and roof of a building and build detachable systems. Instead of using inseparable glues, we’re focussing on reversible systems such as mechanically fixed build-ups which can be detached without contaminating our boards.

The result

We’re still exploring our options. The challenge is to find a solution that keeps membranes, plasterboards, finishes … pure after disassembly, yet stable and firm in place when installed on a building.