Transport: larger loads, fewer kilometers

🡄 Go to sustainability overview

Transport is the third-most-important contributor to the carbon footprint of our PIR insulation boards, although it accounts for only 2.5%. We’ve already taken several measures to reduce our carbon emissions in that area, and we continue to explore other ways to reach net zero.

Projects

We’re collaborating with local partners around our plants to reduce our footprint as much as possible. The idea is to limit unnecessary travel kilometers and find the most efficient way to deliver our lightweight boards to our customers by considering traffic congestion, weather conditions, vehicle capacity, stop priorities and return freight.

Local logistics partners

We partner with several local logistics companies per plant, each specialised in a specific area. That way, we can reduce our total transport distance and optimise our routes to avoid empty returns. We also try to bundle loads wherever possible (by delivering in D+2 instead of D+1).

Lightweight products

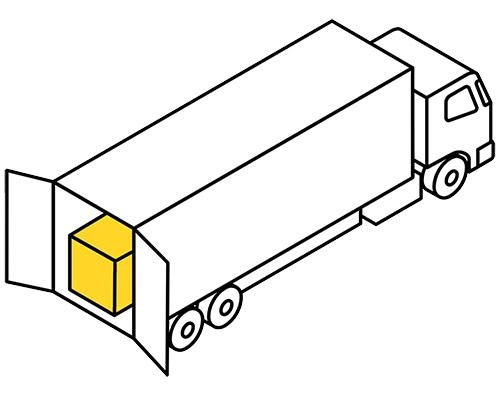

The average weight of our insulation boards is 35 kg/m³. That means a fully loaded truck weighs approximately 2 tonnes, which is peanuts considering the large volume of insulation boards that 1 truck can deliver. And since lightweight loads reduce fuel consumption, this automatically limits the carbon footprint of our transport.