Chemolysis: our gateway to circular insulation

🡄 Go to sustainability overview

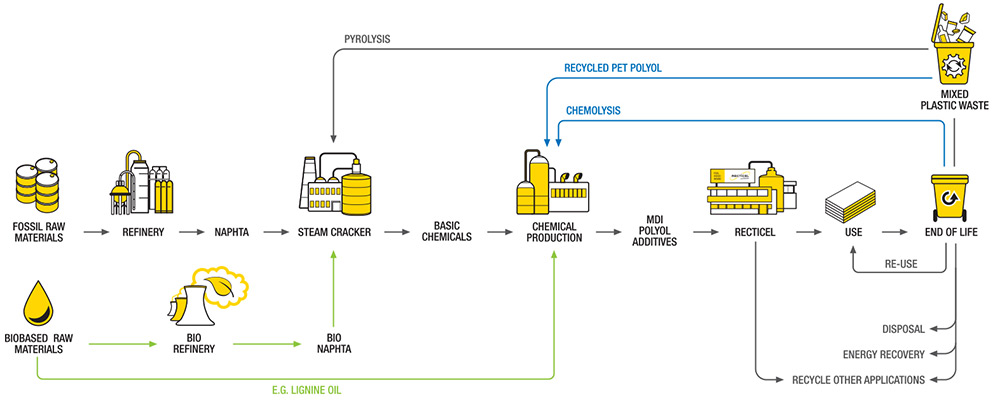

In order to achieve circular insulation, or as we like to call it: fundamentally sustainable insulation, we need to reduce our dependence on fossil fuels and find a way to maximise the value extraction from our end-of-life materials.

And we’re doing it by choosing sustainable partners in every step of our upstream supply chain, and by exploring 4 different routes ourselves:

- Reuse: By applying the principles of eco-design to develop insulation systems that can be reused in a different project.

- Pyrolysis: A recycling process that uses mixed plastic waste to produce naphtha as a feedstock for the manufacturing of MDI and polyol, the basic components of our insulation. Unfortunately, it requires a massive amount of energy, which is why this isn’t our preferred option.

- Biobased raw materials: We’re moving from fossil-based to bio-circular raw materials and are testing the use of lignin to replace fossil-based polyol. conducting tests with lignin oil to replace polyols .

- Chemolysis: A recycling process that returns PIR boards to their original building blocks. This process is not only less energy-intensive than pyrolysis, it can be repeated over and over again. When industrialised, it can be our gateway to circular insulation, and by extension, a sustainable construction industry.

While incineration for energy recovery and recycling in other applications offers a one-time solution, chemolysis can help us create a closed-loop system that keeps our insulation materials in circulation.